Someone took exception to my suggestion on Coffee with Jules that Sonor is likely developing new pedals and hardware. If they want to chime in, I will let that be their call. This isn't an attempt to square off, I just thought that it was worth a deep conversation for those who are interested in a discussion.

The ProLite series has been slated for discontinuation for at least two years. I have no idea if the SQ1 was past of that product lineup change from day or, or if it was later deemed to be a natural addition to the cancelation once the 3 tone wood concept was adopted. But, the point is that the ProLite line is now 13 years old and lots of R&D and planning seems to have been in the works to replace it, though we would probably all agree that a good chunk of time and resources were devoted to the 150th Anniversary products.

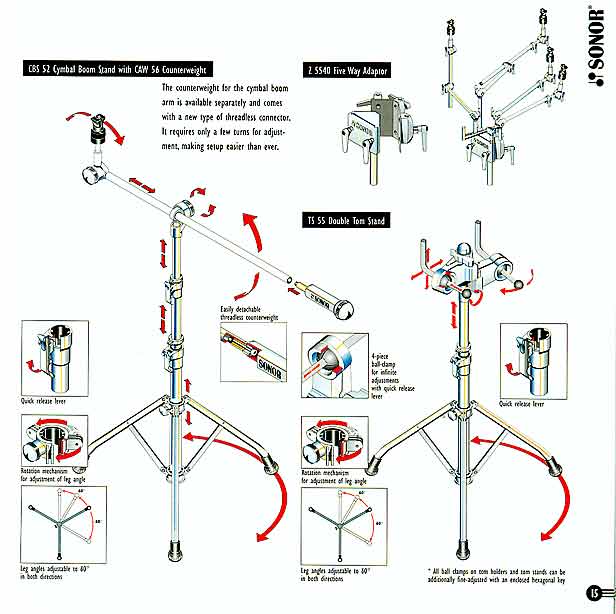

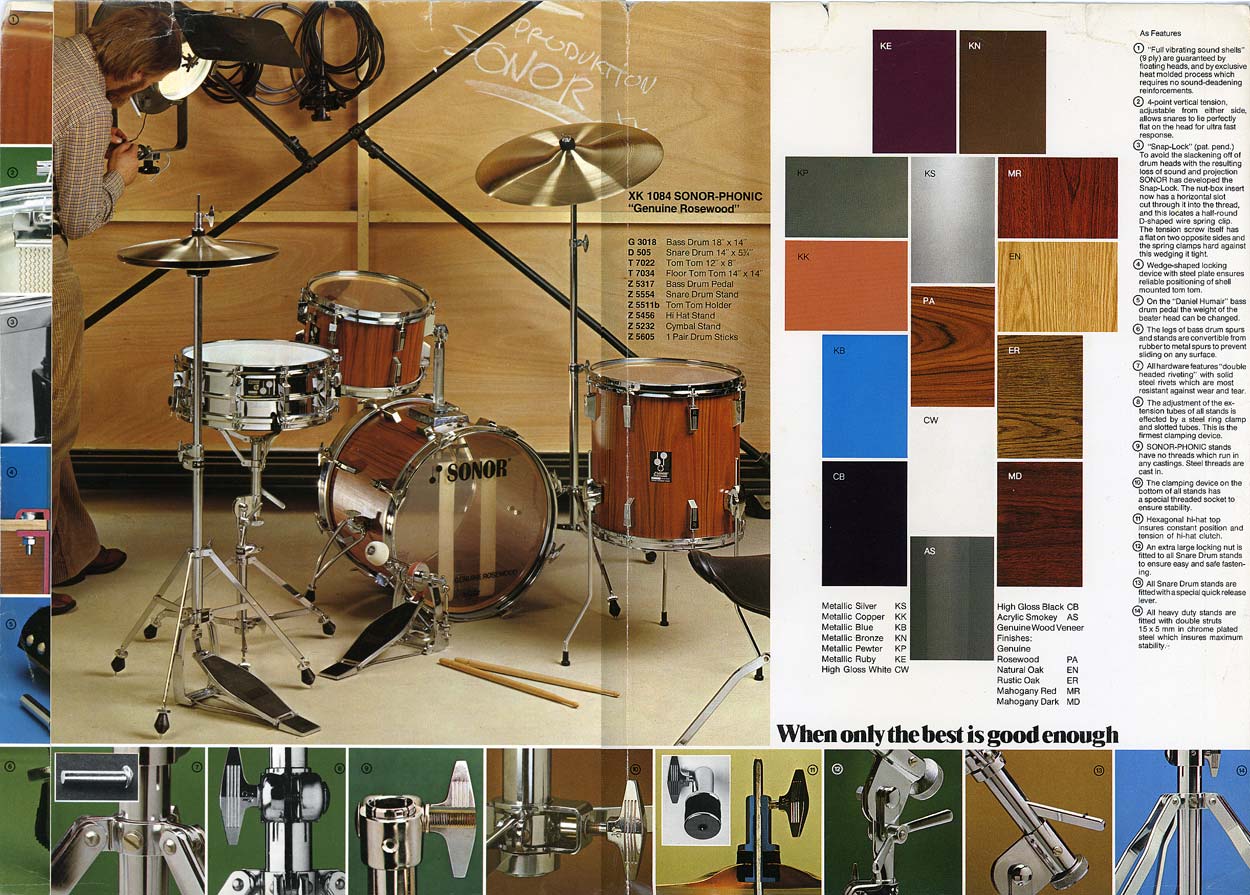

If you take a good look at the time line of German Sonor drums; ProLite has been in the catalog for 13 years, Vintage has been around 10 and SQ1, 8. So, other than some finish options, there has been nothing fresh in the catalog for a while. 600 series hardware hit the catalog almost 23 years ago with only minor changes along the way. All in all, that's a pretty tired catalog.

My speculation that new hardware and pedals may be on the horizon next year is based on some observations and conversations and not just a whimsical assumption that Sonor had manpower to burn up while watching sales slow in response to the world economy. All that said, I do feel like a company has to freshen things up even in tough times just to stay viable. If you have an aging product line and diminishing market share lost to competitors who are building great gear and with healthy artist rosters and product availability, that can create a vacuum, it would seem.

I look forward to seeing what does get released, if anything in the coming year or two. Things I would expect to see include potentially a high end line (solid rivets as with 600 series) possibly made fully in China. At this point, almost EVERYONE is sourcing their metal components and hardware items from Asia and I am not sure there is still a virtue in German assembled hardware for the typical buying in 2025. Certainly not at such high prices.

When the Force 3000 hardware went from Germany to Asia, there was no loss of quality, yet a drastic drop in street prices. While this wouldn't be music to the ears of old school Sonor guys; we aren't the majority of the buying public any more. If you can have rock solid hardware at half or less (not factoring in tariffs) of the price, what have you accomplished by paying a bigger price for something for the sake of it being German made? Again, we are talking about hardware, not the construction of the drums and drum shells.

Another gripe I have had about the 600/Basic Arm Series is limited availability in the US. Sooner or later you can find all the pieces, but it's not always going to happen that all the components you want to customize your stands will be there when you want them. Add to that, that most manufacturers have far more components and accessories and that really leaves a gaping hole in the Sonor hardware line in comparison. When I went to Fork's drum closet, the one brand I did not see with an elaborate wall display of items was Sonor. There were serious representations from most other brands. So, maybe we have that forthcoming.

Aside from a stale and arguably deficient hardware offering is that fact that for a few reasons, many Sonor drummers don't use Sonor hardware. Pedals may be even worse. There are a host of drummer who use non-Sonor pedals with their Sonor gear, and I would BET that new options are well in the works. I don't have that on an official level, and if I did I wouldn't be talking about it at all. But, taking pieces of the puzzle and connecting them, that's what I think we have to look forward to in the somewhat near(ish) future.

Does anyone know of we are getting any more 150th gear? Are there any more trade shows left this year to premiere anything else?